vickers hardness test experiment conclusion|is 1501 pdf free download : purchaser Perform analysis from Vickers hardness testing data. Hardness is a characteristic of a material not a physical property. Hardness is defined as resistance to indentation and determined by measuring the depth of the .

WEB21 de mai. de 2022 · The Sims 4 ; Downloads - The Sims 4 ; Mia Khalifa Large Poster object Mia Khalifa Large Poster. poster; pornstar; mia khalifa; By Guest, May 21, 2022 in Downloads - The Sims 4. Follow on Followers 0. Recommended Posts. Guest Posted May 21, 2022. Guest. Guests; Share; Posted May 21, 2022. Mia Khalifa Large Poster

{plog:ftitle_list}

webAcesse aqui o WEBISS, sistema para emissão de NFS-e. Clique aqui para acessar. Para acessar emitir a certidão negativa clique aqui . - Pedido de Viabilidade. * Faça a consulta .

Experiment objective: Vickers hardness tests are used to gauge a material's hardness, and that is its main goal. For quality assurance, choosing materials, and engineering design, this information is essential. A material's strength, resistance to wear, and durability can be .Conclusion: The purpose of this experiment was to determine which of the five .Perform analysis from Vickers hardness testing data. Hardness is a characteristic .Conclusion: The purpose of this experiment was to determine which of the five materials tested was most suitable for the production of 500 HV30 automobile gears. After careful experimentation, calculations and analyzing it was .

(I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.Perform analysis from Vickers hardness testing data. Hardness is a characteristic of a material not a physical property. Hardness is defined as resistance to indentation and determined by measuring the depth of the .

Vickers Hardness Test. The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness . Three-dimensional finite element-based numerical analysis of Vickers indenter hardness test was conducted to investigate the effect of frictional conditions and material anisotropy on.VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The .

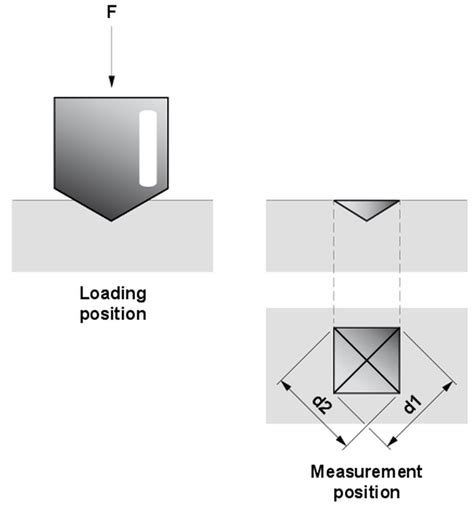

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F [N]), the indentation .Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and .

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees .How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . The Vickers hardness test is a versatile hardness test method, used for both macro and .Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be .

The Vickers Hardness Testing is a cornerstone technique for evaluating the hardness of assorted materials, mainly metals and their types. Formulated in 1921 as a simpler recourse to the Brinell test, it estimates a material’s resistance to deformation under a consistent burden.Conclusion. The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The Vickers hardness test allows engineers to inspect materials before they undergo production or post-production processes such as heat .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.Experiment No. 02 ROCKWELL HARDNESS TEST OF A GIVEN SAMPLE Introduction: Hardness of a material is generally defined as resistance to the permanent deformation such as indentation, wear, abrasion and scratch under static and dynamic load. . Conclusion: For hard materials, diamond cone indenter with C scale (black graduation) is used applying . View Lab - report 1 (Vickers Hardness Test).docx from BMM 1511 at University of Malaysia, Pahang. BMM1511 Engineering Mechanics Lab 1 Lab E1 Vickers Hardness Test Section/Group Section 02 Group . 5.0 CONCLUSION In this experiment, when the Vickers hardness of specimen position for welded (butt joint) is decrease, the Brinell hardness and .Experiment on Vickers hardness test. Group 10 Samuel Olakanmi (202202443) Atlarelang Mhateng (202206923) Golebaone Motsumi (202206035) Katlo Morwamang(20200402) Ame Seamolo(202304327) Abstract Mechanical hardness testing is important in the evaluation of properties of metallic materials. Determining the hardness of a

For most hardness testing, 50 kg is maximum. The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH). The hardness number can be calculated by the load over the surface area of the indentation .

Conclusion: The hardness test experiment was done using a Brinell and a Rockwell Testers. The data obtained was recorded and compared. The experimental and referenced values for each metal were compared. Table 2 showed that the percent differences for Rockwell Test were smaller than for the Brinell test. This concludes that the Rockwell test is .15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .

The Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range.How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. . when drawing conclusions of a hardness test, you should always evaluate the quantitative value in relation to: The given load on the indenter . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from . In conclusion, the Vickers hardness testing method is a powerful technique for assessing the hardness of various materials. Its principles are grounded in precise indentation measurements, allowing for accurate .

vickers hardness test procedure pdf

Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

The main objective of this experiment is to determine the hardness strength of a material by Vickers testing methods. . George E. Sandland who studied at Vickers Ltd. developed an alternative to Brinell hardness in 1921 which was named as Vickers hardness. In the Vickers test, the entire calculation is independent of the size of the indenter . Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s experience. In .The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface.3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Brinell test in Sweden in 1900. The oldes t of the hardness test methods in common use today, the Brinell test is frequently used to determine the hardness of forgings and castings that have a grain structure too course for Rockwell or Vickers testing (http ://www.instron.co.uk ). 2.2. Case hardening improves both the wear Vickers hardness testing also is known as the Diamond pyramid hardness test. Because we use the Diamond pyramid as the indenter. The same testing machine which is used for the Brinell hardness testing machine can be used for the Vicker’s hardness test also.; Unlike Brinell hardness testing, we do not need to change the indenter for the different materials. we .With its wide range of tests and commitment to top-notch practices, Infinita Lab is ready to support this need, driving innovation and ensuring quality in a variety of fields. Also learn about differences in Rockwell, Brinell, and Vickers metal hardness test. Video 01: Hardness testing (Brinell, Vickers and Rockwell test method)Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: It is similar in principle to Rockwell hardness test, but utilizes a different indentor and different magnitudes of loads.

refractometer buy ireland

refractometer by sungrow

webSoy HOPA y me encantan los dinosaurios.

vickers hardness test experiment conclusion|is 1501 pdf free download